Over 1,000 rooms surrounded by meters of steel-enforced concrete. Similar nuclear reactors are still in operation in Germany

Important facts about the Zwentendorf Nuclear Reactor:

- Type: Boiling Water Reactor

- 4 Turbines (1 high pressure turbine, 3 coupled low pressure turbines)

- Total reactor area: 60 acres

- The building complex has over 1,000 rooms that were constructed by up to three meters of steel-enforced concrete (cell phones do not function within the reactor)

- The same type of nuclear reactors are in operation in Germany (Isar 1 and Philippsburg 1)

- Diameter of the reactor core: 6.5 meters; 20 meters high

- Cooling pool with 60 tons of heavy surface shell

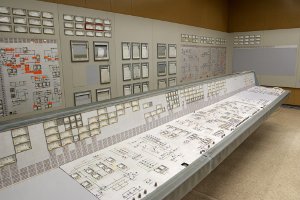

- All essential parts of the nuclear power plant are original and well preserved, including the reactor, the main control room, the nuclear fuel element dry repository, and the wet well

- When operational, the pressure container in Zwentendorf was to be filled to two thirds capacity with pre-heated water. The Uranium Dioxide fuel rods, enriched by up to 4.02 percent Uranium 235 would have been subject to atomic fusion, creating sufficient heat to boil the water and producing steam, which then would have driven the turbines. After passing through the turbines, the steam (about 7,000 tons per hour) would have been returned to a fluid state by the action of the cooling water in the condenser and reintegrated into the cycle.

- The steam in such a reactor reaches a temperature of 270 degrees Celsius and the pressure would have been 80 Bar in order to operate the four turbines.

- The reactor was conceived to provide 732 megawatts of electricity – enough for 1.8 million households.

- The same type of reactor in Brunsbüttel, Germany, which commenced operation in 1977, has generated about 130,000 gigawatt hours of electricity. That is more than double the current total electric power generated annually in Austria, and represents a total value of approximately 9.1 billion Euros.

- Solar power instead of nuclear energy: A photovoltaic plant was put into operation on the roof and the outer portions of the plant in 2009. It provides an average of 180,000 kilowatts of electrical energy annually.